Flow curves models

More than 500 flow curve data sets

The StahlDat SX provides flow curves for different steels in various casting and cold and hot formed states. The flow curves were kindly provided by the Institute for Metal Forming of the TU Bergakademie Freiberg. They are the result of decades of experience in this field and are also internationally regarded as a solid basis for the design of forming processes.

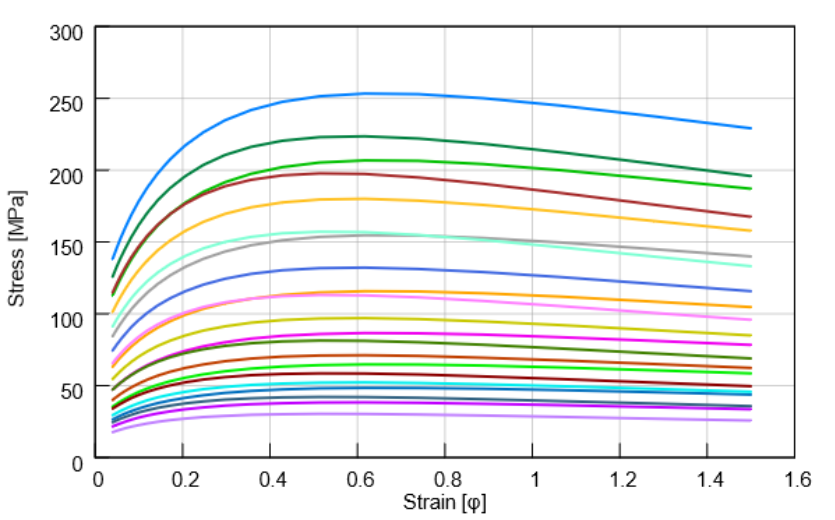

Fig. 1: Flow Curves

Fig. 1: Flow Curves

Parametrization of flow curves

All flow curves based upon the temperature, strain, and strain rate dependent Hensel Spittel model (IMF TU Freiberg).

Within the scope of the validity of the model, any flow curves for steel can be generated and compared with each other by using the Parametrizator function.

Flow curves are available for more than 150 steels for different heat treatment conditions. The flow curve data sets are directly linked to the steels of the Register of European Steels.